연구개발

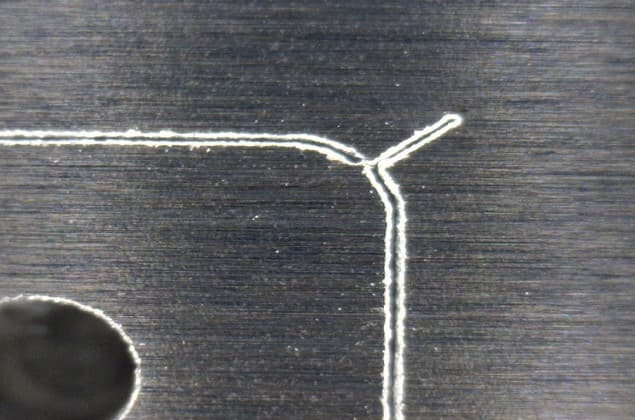

High Speed Laser Direct Imager

.avif&w=3840&q=75&dpl=dpl_n7KZ9G32dhvv1Btgk9bmRuTXjq85)

.avif&w=3840&q=75&dpl=dpl_n7KZ9G32dhvv1Btgk9bmRuTXjq85)

Competitiveness

In manual work with conventional UV scattered light, automated work is possible using a 405 nm laser light source

Can be minimised and microcircuited

Productivity and quality improvement

Fast productivity of 12 sec/side without the use of a separate master film

Blocking the foreign body funnel to improve the quality level

Vacuum Substrate Lamination using Equipment

Competitiveness

Reduces product stress compared to traditional hot presses and quick presses

Solving resin problems with emissions and bubbles

Quality Improvement

Hot press, Reduces crack problems that are problematic during work

Pressurization using pressure and heat reduces bubble problems

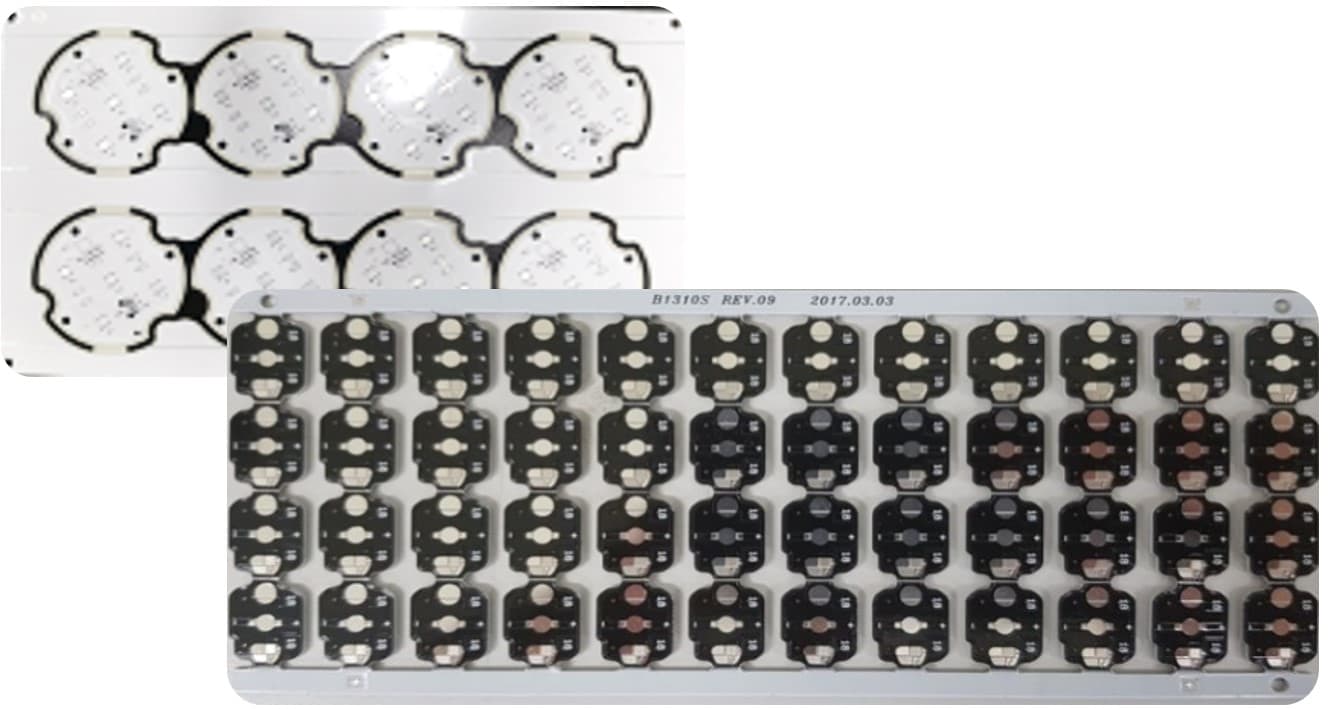

Insulator Filling Type Double-sided METAL PCB

Competitiveness

When the metal PCB is composed of two sides, the existing ink filling method has a long cost and process procedure

This is changed to the RCC filling method to simplify the process and strengthen reliability

Quality Improvement

Compared to Hole Plugging, RCC is used, which also increases fillability and resin curing

Copper plating and bondability improvement

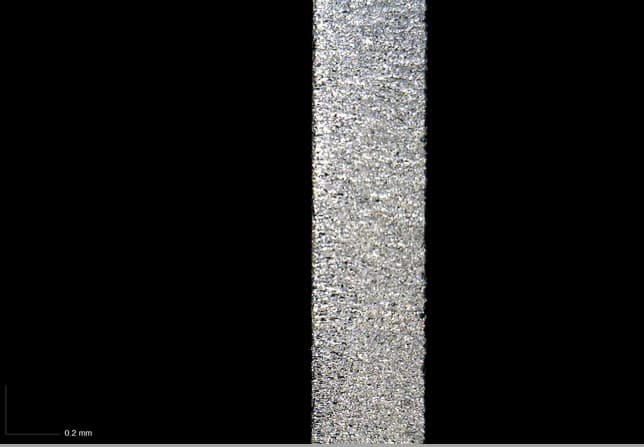

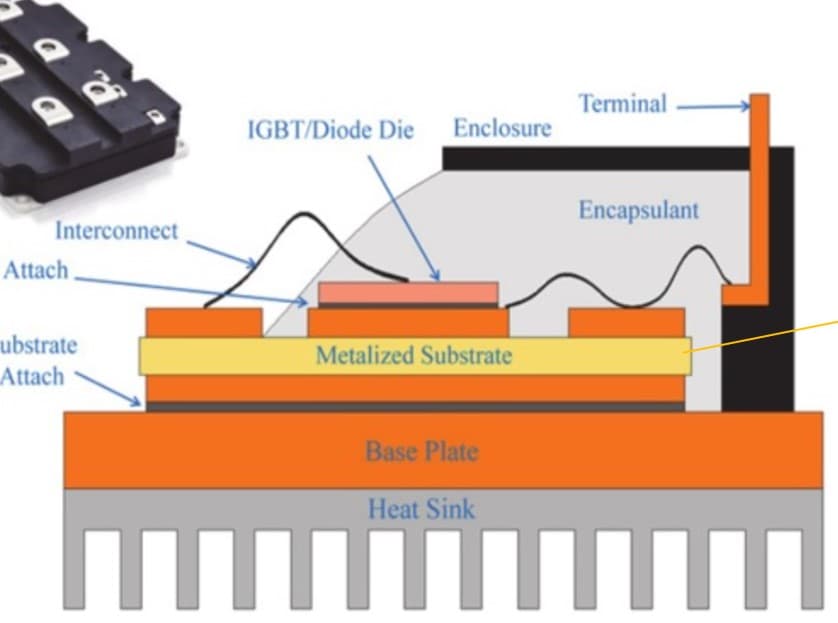

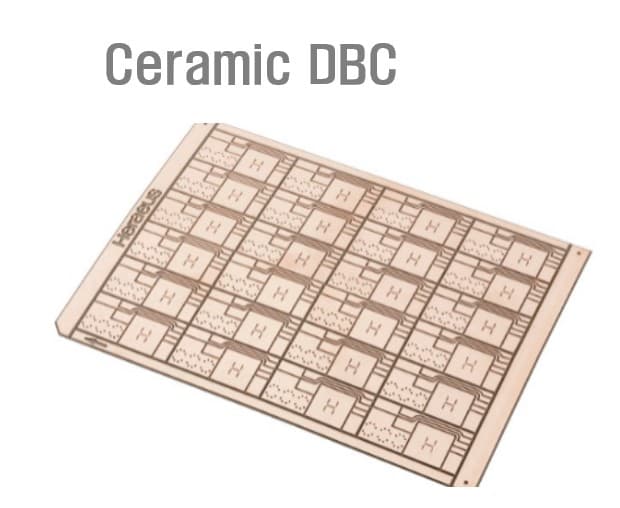

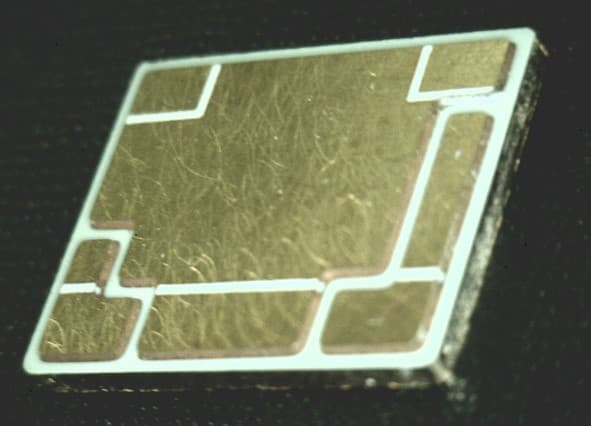

Replace Ceramic DBC : 9 Oz High heat dissipation IMS

Competitiveness

Securing a more simplified process of the existing ceramic DBC manufacturing process

Due to the characteristics of ceramics, it can compensate for the disadvantages of cracking and large-scale processing, opening up the existing DBC market

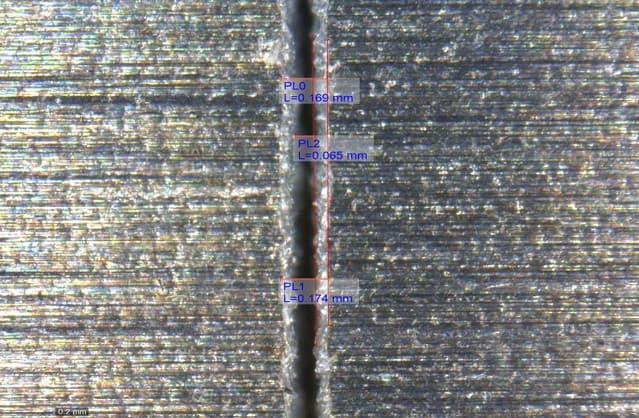

Development Challenges

Development of 5.0 W/mK ceramic resin insulation layer, which is an improvement over the existing 3.0 W/mK, is underway

6~9 Oz Heavy Copper, Development of circuit-forming machinability is underway

Laser Bridge Kit of Metal PCB